The Smart Start to Industrial Scalability

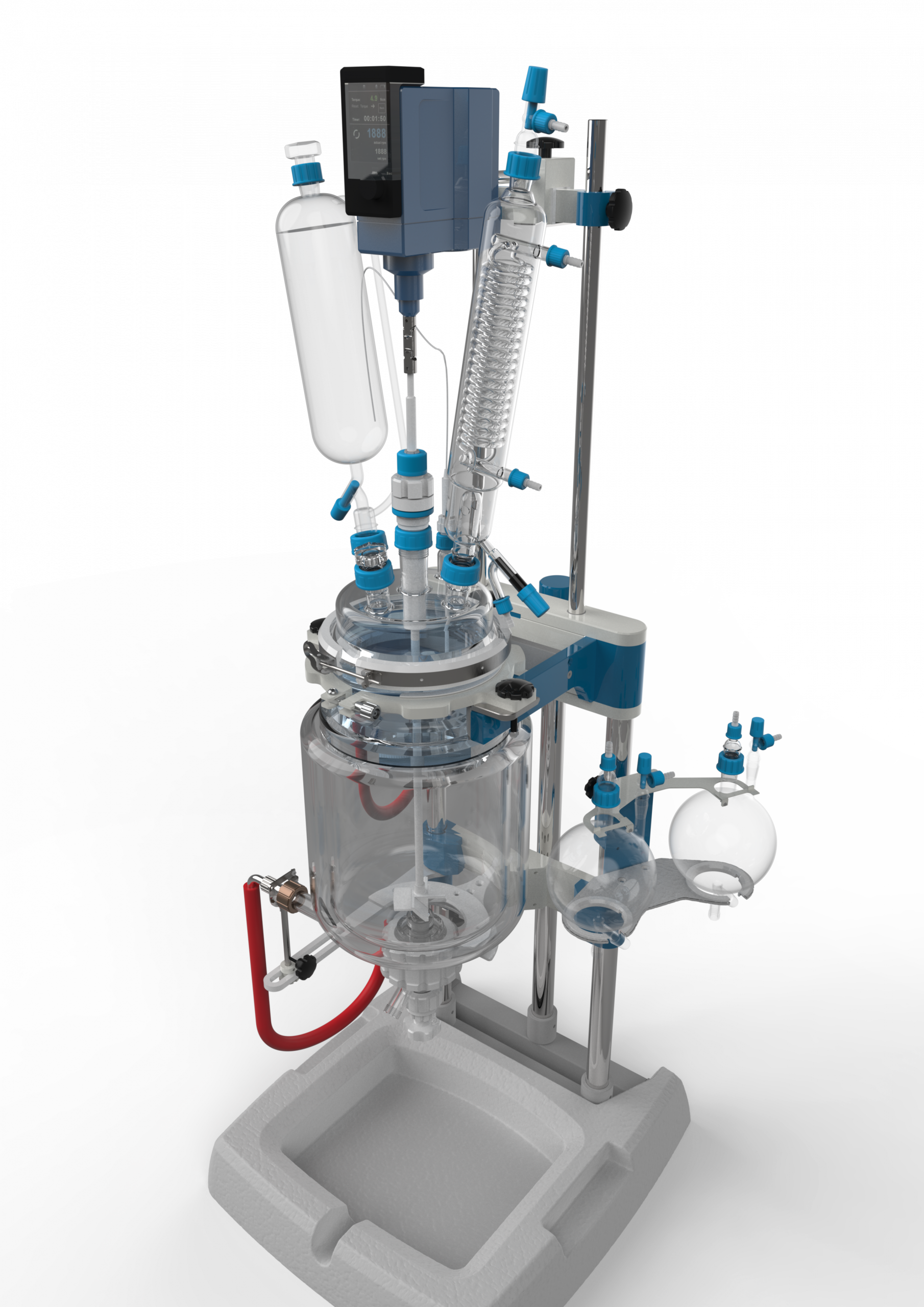

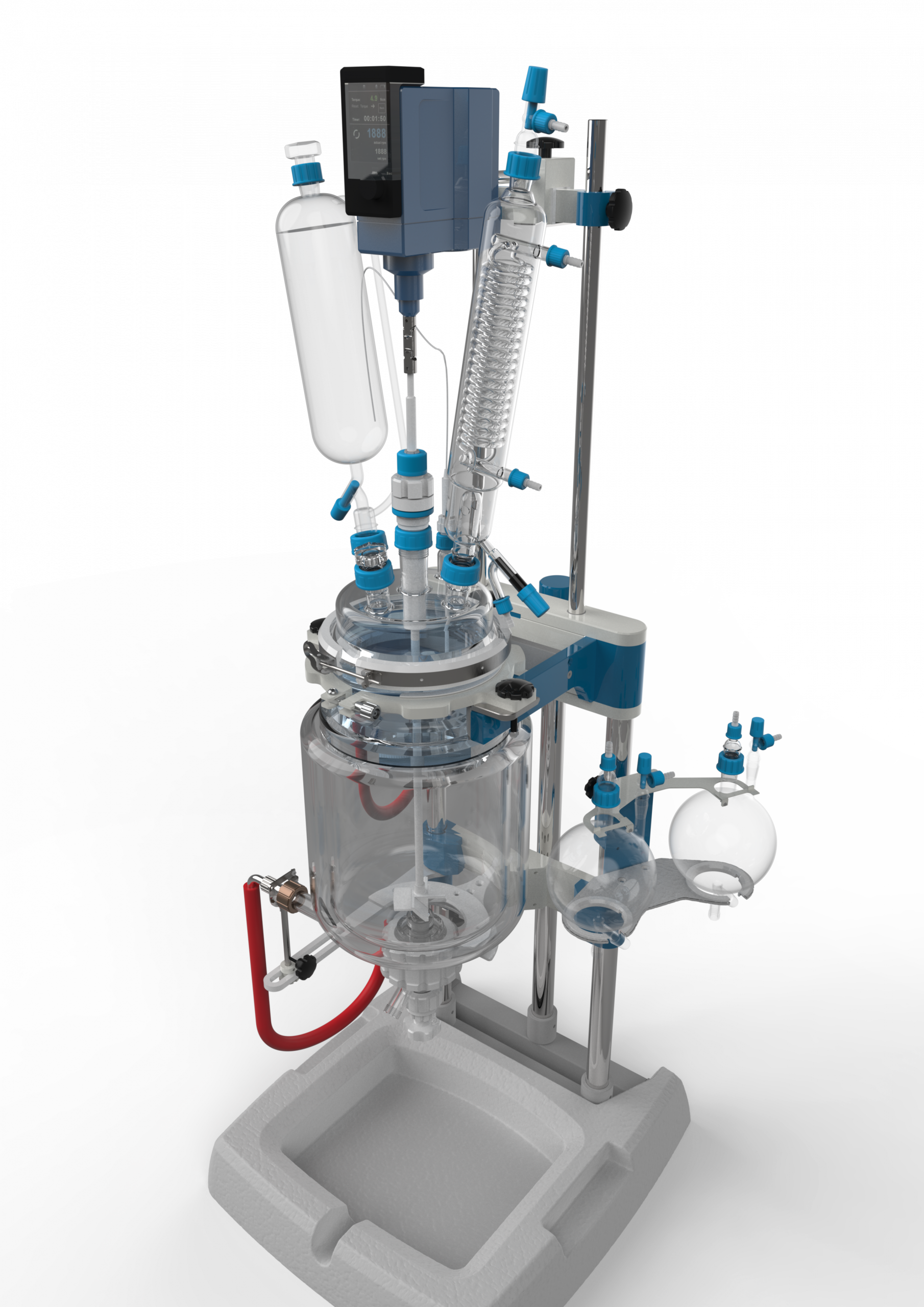

Introducing COMET, the pilot lab reactor designed to bridge the gap between laboratory innovation and industrial scalability. Engineered to maintain precise proportions for process scalability, COMET ensures that your experiments translate seamlessly to larger production volumes. With its user-friendly design, handling becomes effortless, enhancing usability for all operators. Offering versatility with low maintenance and skid-mounted designs, COMET also allows easy mobility and integration into any workflow. As the first step towards industrial scale-up, COMET facilitates larger reaction scalability, accommodating volumes from 10 to 20 liters. Experience the future of pilot testing with COMET, where every detail is optimized for efficiency and growth in your processes.

| Part Code | Temperature DegC | Pressure BarG | Flange Dia (MM) | LXBXH (MM) |

|---|---|---|---|---|

| BLMRPLR010XJ000000 | -40 C to 200 C | Vacuum to 0.5 | 200 | 715X720X1800 |

| BLMRPLR015XJ000000 | -40 C to 200 C | Vacuum to 0.6 | 200 | 715X720X1801 |

| BLMRPLR020XJ000000 | -40 C to 200 C | Vacuum to 0.7 | 200 | 715X720X1802 |